-

Lame industriali

Ottimizza le prestazioni delle tue lame industriali con noi: Affilatura e Riaffilatura lame circolari industriali

-

Lame HSS

Ottimizza le Prestazioni delle tue Lame Circolari HSS con Starcut: Affilatura e Riaffilatura Professionale

-

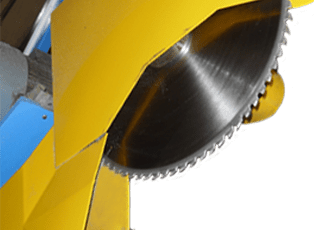

Lame circolari

Ottieni le migliori prestazioni con le lame circolari di Starcut: servizi di Affilatura, Riaffilatura e Riparazione Professionale

-

BIG SAW BLADES AND SPECIAL TOOLS

We manufacture large diameter saw blades for every market that needs big cutting or special working

More -

CIRCULAR AND SPECIAL KNIVES

Circular Knives for tubes and solid cutting Industrial Knives to work wood - plastics - maetal - light alloy Production of special tools as per drawing !!!

More

Segmental saw blades

Segmental circular saw blades for metals cutting, toothings, cutting geometries and sizes of discs on request according to steel type and section to be cut, maximum diameter of 2015 mm.

Segmental saw blades are circular cutting tools that are designed with toothed segments fixed on body disk with steel rivets, these blades are used in several iron and steel industries where a high level of precision and heavy cut-off on solid rods, large pipes and drawn steel are required.

Each segment is made in HSS high-speed steel and sharpened with special shape for every material that needs to be worked, the high-quality production of segmental saw blades result in longer life and improved cutting efficiency, leading to reduced downtime and increased productivity.

These tools are also used for brass, copper and aluminium cutting, it is important to select the appropriate segmental saw blade to achieve the best result. Factors such as the material being cut, material thickness, feed rate and required precision of the cut should all be considered when selecting this tool.

Proper maintenance and sharpening of the blade are important for optimal performance and longevity.